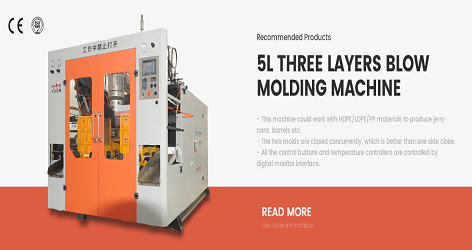

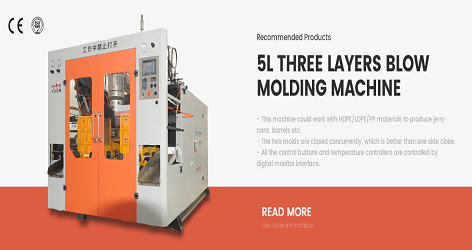

2020-11-22 This equipment is suitable for blowing bottles, barrels and pots within 150mL-10L. It can produce one to three layers (multi-layer products such as cladding level line and high barrier), and the equipment adopts Mitsubishi PLC computer control system. The motion system adopts advanced Inovance or Mi

Read More

2020-11-15 Daily check points1. Check whether the temperature rise of the screw barrel, the current and the cooling fan are normal.2. Check the liquid level of the oil source tank at 40%-65%.3. Check the oil-water separator at the air source inlet of the equipment to check and drain water.4. Check the lubricat

Read More

2020-11-07 The injection molding machine and the blow molding machine are two different process machines. The temperature adjusted by the machine is different during the production of the product. If the material is returned to another process, it will cause great damage to the mold and the machine! It is not

Read More

2020-11-01 1. Precautions for starting hollow blow molding 1. Personnel without professional training shall not operate the blow molding machine without authorization. 2. Before the machine is turned on, open the cooling water valve to ensure that the cooling water channel is unblocked; turn on the internal po

Read More

2020-10-25 First of all, let’s talk about the blow molding machine. The blow molding machine can heat and soften the raw material, extrude the tubular parison through the extrusion head, inject it into the mold, lock the mold, and inflate the parison with compressed air. Stick to the inner wall of the mold, an

Read More

2020-10-18 How often does it take to maintain the bottle blowing machine?There is no fixed time and cycle limit.Although the blow molding machine is relatively simple to operate, its components and system structure are more complex. Different components and systems require different levels of maintenance work,

Read More